Card personalization and coding

[Services]

Aplicard offers the possibility to customize plastic cards according to the indications of our customers, using industrial equipment both for initial large-scale issuance as well as for the subsequent small lots. The customizations can be graphical or electrical.

Monochrome thermal printing: a printing method that uses heat and pressure to melt the resin of the ribbon onto the PVC of the card and thus print the customer’s variable data as name, surname, customer number.

Sublimation color: printing method when the iodine pigments of the ribbon pass from solid to gaseous state by applying heat and pressure on the PVC of the card. After color printing, a 0.025 micron film is transferred to prevent iodine pigments from being sublimated again due to the heat. The print quality is 300 dpi. Normally, it is used to print a photo of the card holder for identification purposes.

Electrical personalization of the chip: we have equipment to customize different types of contact and proximity chip according to the needs of our customers.

Signature panel: once applied it allows the user of the card to be able to sign or write on its surface. It can be white or transparent and of different sizes.

Scratch off: thin film, usually made from latex, applied on the surface of the card to hide information. It can be easily removed by scratching.

Two-dimensional bar code: It is a multifilament code, continuous, of variable length, with a high capacity of data storage. The code contains all the information, it is not necessary to consult a document.

Customer Loyalty (Handling)

Once the cards have been manufactured, we offer you the possibility to send them to your customers by mail so that they can receive them at their homes, and benefit from that moment from the advantages of being the holder.

The services we offer are:

- Card customization: variable holder data, barcode printing, magnetic stripe encoding, contact or proximity chip.

- Envelope and letter printing with variable data.

- Matching, card affixing, folding, enveloping and sorting by zip code, postage and shipping.

- Incident management and shipment status report.

All this process is carried out under the strictest confidentiality and security measures to protect the data of its clients.

Mailings with card

At Aplicard we specialize in executing marketing campaigns that include sending any type of card (loyalty, gift, mutuality, health, and partner) to our clients, either in a single shipment or in small lots during the year. This process can be automatic or manual.

Automated mailings

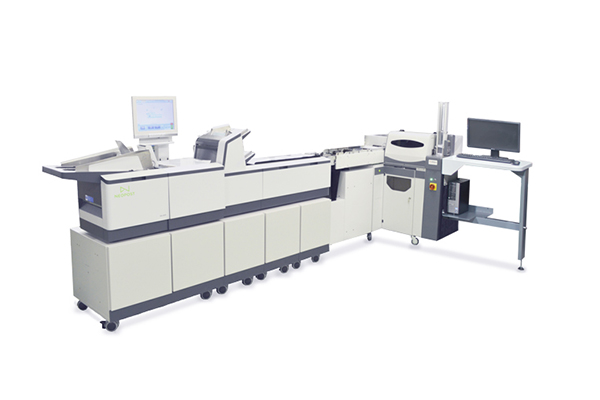

We carry out the automated process of mail sending of PVC cards, from the databases management to postal mailing.

When the process can be automated with our personalization and enveloping equipment, matching the card and a letter is precise, the production time is reduced and the cost decreases.

We have the most technologically advanced equipment that allows us to obtain high level of the production at low cost. The automated processes are:

– Customization of cards with variable data and its coding

– Custom laser cards

– Secure card´s matching

– Attach documentation

– Folding

– Envelope

Mailings and handling

When the elements to be matched have weights, shapes and measures that cannot be mechanically handled, we have qualified employees to perform this type of work.

– Assemble gift sets

– Creation of welcome packs and promo packs

– Packaging in film

– Special handles and fittings

– Special inserts

– Product labels